Shows your fluid the

Correct way

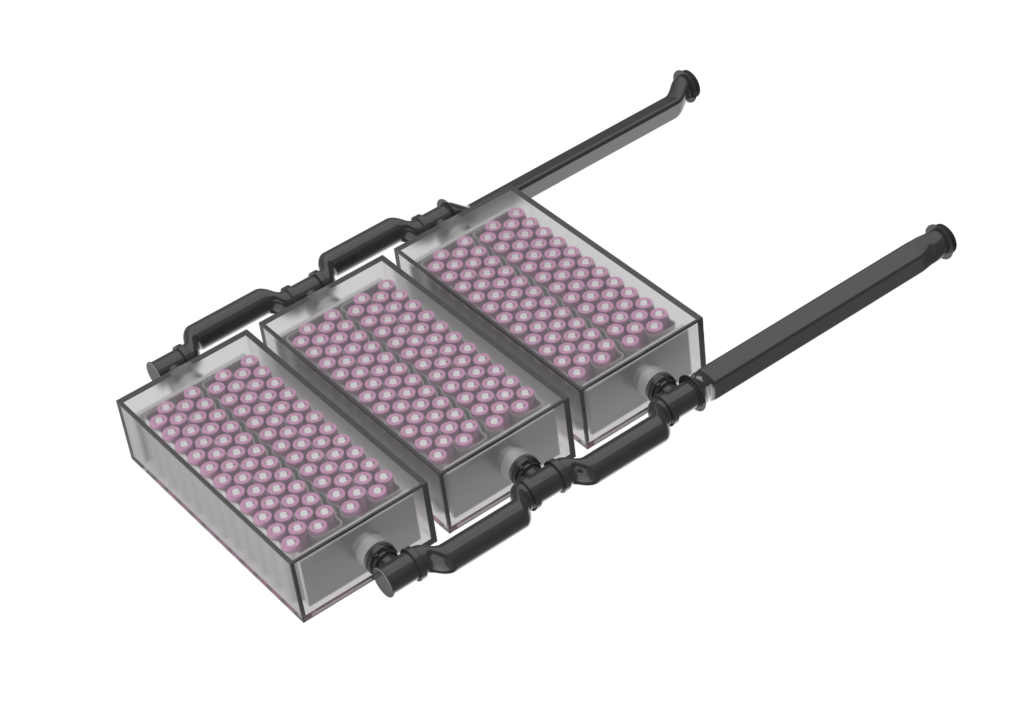

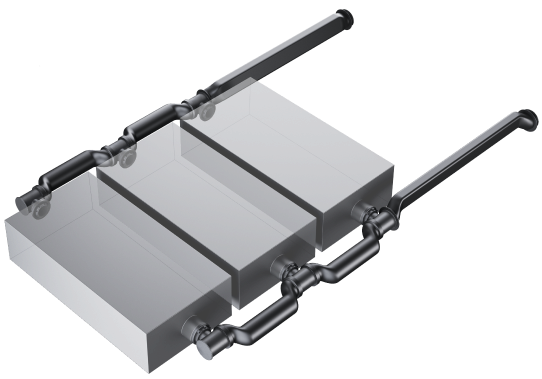

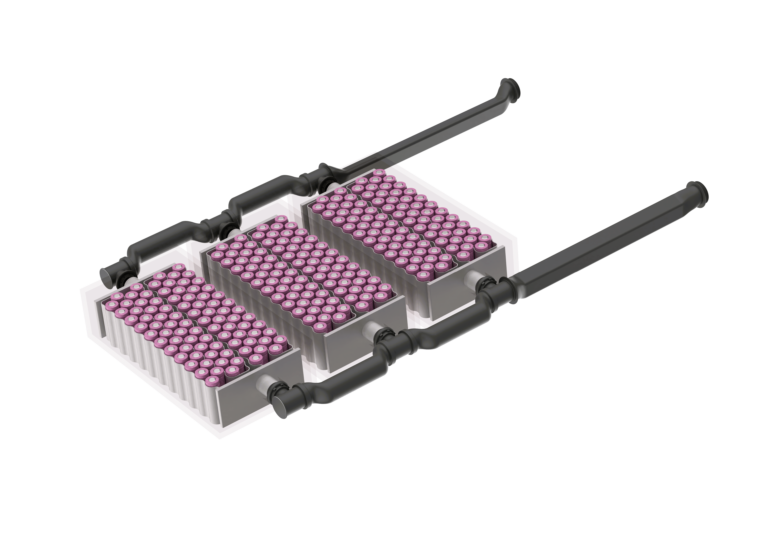

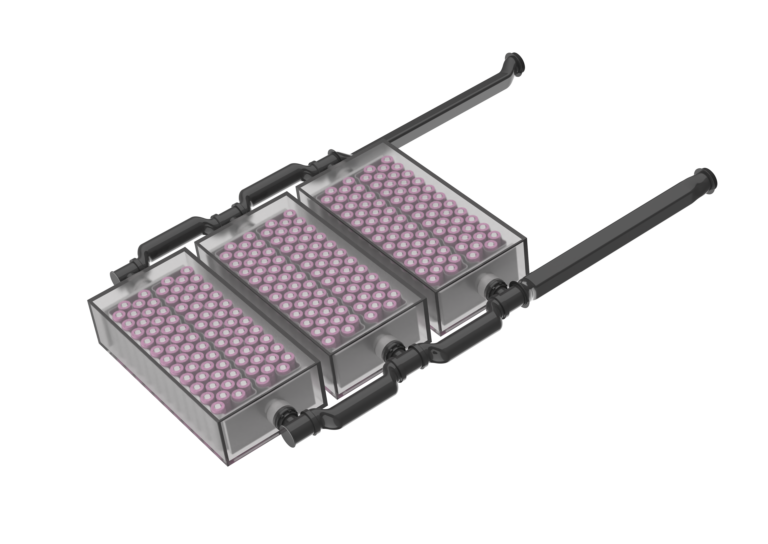

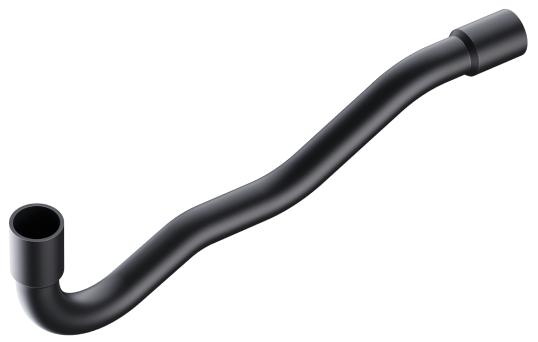

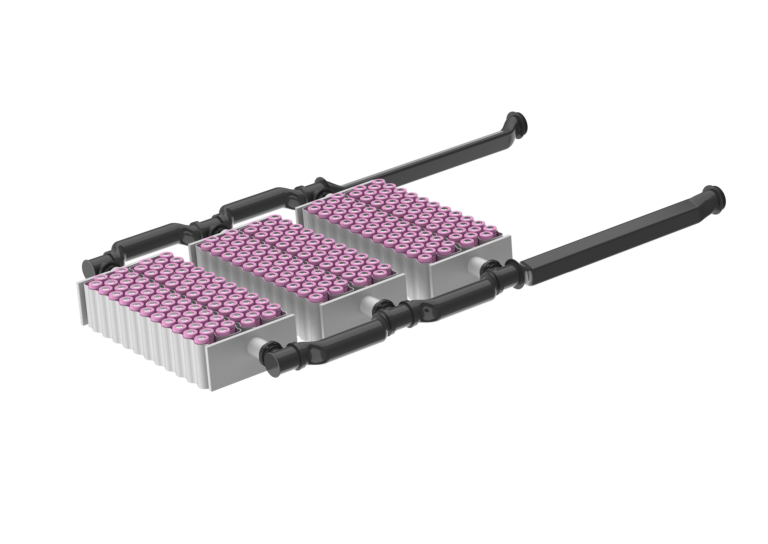

The coolant circuit in a battery system requires thermal control at multiple points throughout the installation.Our advanced cooling tubes leverage state-of-the-art manufacturing processes, including blow molding (conventional and suction), extrusion, and thermoforming, to deliver reliable thermal management solutions for coolant fluid distribution. As your trusted partner, we are dedicated to providing innovative and effective solutions for your cooling needs.

Reutter + ITIB Group is developing and producing battery vents and cooling tubes according to your specific requirements as well as offering off the shelf application.

Get in touch with our engineering team to address your challenge to us!

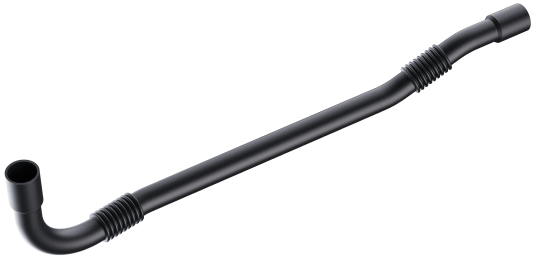

Cooling tubes

The thermal management is crucial for the efficiency of battery-powered products. Ensuring optimal operating temperatures during use and charging is essential for peak performance. To distribute the coolant fluid inside the battery pack, our hoses do a great job.

Design will be adepted to fit to customer environment

Conventional blow molded

Extruded (smooth /corrugated)

Quick connectors assembled

All extrudable plastic grades can be processed

Water/Glycol or Di-Electric cooling fluids

Suction blow molded

Thermo-formed

Tightness tests according specification

Market known connectors can be implemented / used

Design will be adepted to fit to customer environment

Conventional blow molded

Extruded (smooth /corrugated)

Quick connectors assembled

All extrudable plastic grades can be processed

Water/Glycol or Di-Electric cooling fluids

Suction blow molded

Thermo-formed

Tightness tests according specification

Market known connectors can be implemented / used

Contact us

Felix Schulze

Sales Director

- +49 7195 95987-63

- +49 172 1788 766

- felix.schulze@reutter-group.com

-

Reutter GmbH

Hans-Paul-Kaysser Str.10

71397 Leutenbach - Nellmersbach

Germany

Maximilian Kraus

Head of Innovation

- +49 7195 95987-68

- +49 151 18867 406

- maximilian.kraus@reutter-group.com

-

Reutter GmbH

Hans-Paul-Kaysser Str.10

71397 Leutenbach - Nellmersbach

Germany

Mark Schiefer

Head of Innovation

- +43 6412 7824-11

- +49 160 91828 531

- mark.schiefer@reutter-group.com

-

Reutter GmbH

Hans-Paul-Kaysser Str.10

71397 Leutenbach - Nellmersbach

Germany

About us

What we do

REUTTER / ITIB is a modern company, firmly established in Europe and hosting 6 locations worldwide. Innovative solutions have made us one of the leading companies in our specific industry. Our key area of operations is in developing and producing parts, mostly made of plastic using injection molding, extrusion and blow molding.

Reutter / ITIB Group is developing and producing the following components and systems for global automotive industries:

- Battery vent / burst valves

- Coolant / Radiator caps

- Coolant pipes / Coolant pipe systems

- Adblue / SCR caps

- Adblue / SCR filling systems

- Oil caps

- Vents for other application

- Truck tank caps & filler necks

- Air ducts (Engine/Cockpit)

How we do

Having our background in the standard internal combustion engine area, we as well develop and transform ourself into a reliable partner for the changed challenges coming up with the battery electric vehicle needs. Our group is ideally positioned to develop and produce battery vent valves in a large scale, since the product is combining characteristics, functions and technologies that are well known throughout the existing product portfolio of our group.

Moreover Reutter / ITIB is in position to develop and produce battery coolant systems. Our advanced cooling tubes leverage state-of-the-art manufacturing processes, including blow molding, extrusion, and thermoforming, to deliver reliable thermal management solutions for coolant fluid distribution. As your trusted partner, we are dedicated to providing innovative and effective solutions for your cooling needs.

Global Foot Print

Designed and validated in Germany our cooling pipes can be produced in 4 plants to satisfy world wide demand:

- Poland

- Italy

- Mexico

- India

Your specific RFQ or Project will be supervised by German Sales and Project Management resources that are steering engineering and industrial implementation teams for above mentioned 4 plants. Our Project Managers are your single point of contact and are securing communication is at the point and customer specifications and requirements are well understood and respected.